Putting staff safety first with cutting-edge drone technology

Cutting edge technology is helping PD Ports enhance staff safety at its Felixstowe warehouse – removing the need to work at height in order to perform important stock counts.

The logistics provider – one of the UK’s major port groups with 11 locations across the UK – puts employee safety at the heart of its operations, and has been actively searching for ways to mitigate risks team members faced when conducting daily tasks.

Stock counts were identified as a key area to implement technology, because they require staff to work at height on scissor lifts.

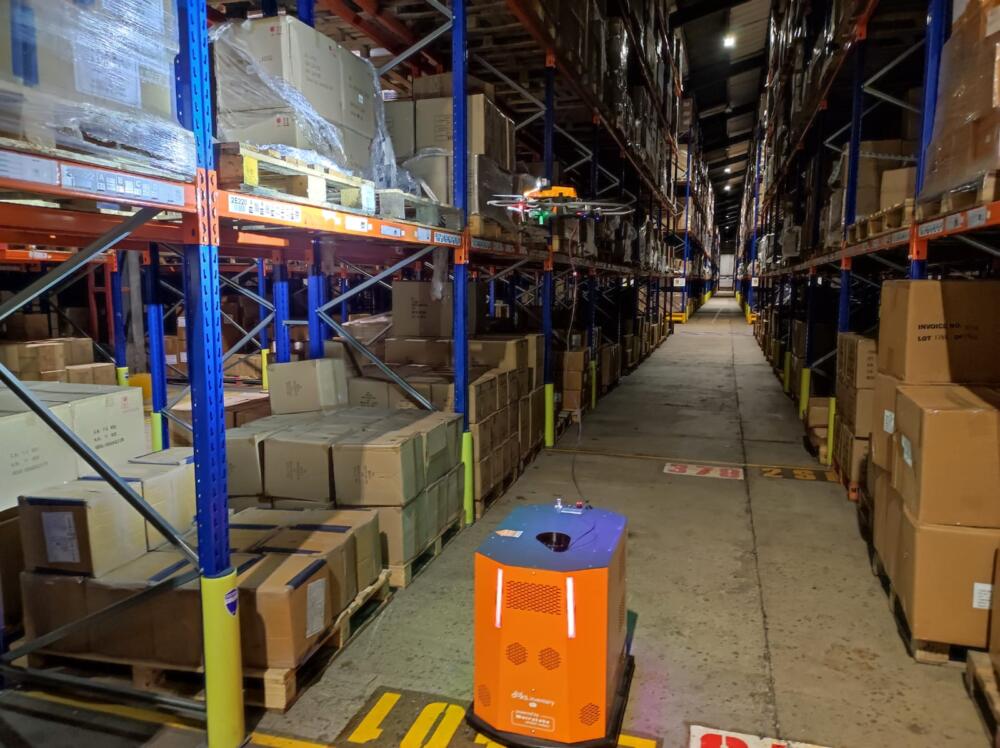

The company has worked with warehouse automation experts RAWview to implement a new drone stock counting system, the inventAIRy XL, to increase efficiency and accuracy, reduce risks and reduce carbon emissions.

PD Ports stock control and systems manager Jonathan Borg said: “The best-case scenario is always to eliminate the risk wherever possible.”

He added: “Some pallet racking in our Felixstowe warehouse goes up to 8m high, which involves an element of risk because it involves our operatives spending a significant amount of time working at height on a scissor lift.

“We have very high safety standards, but the best-case scenario is always to eliminate the risk wherever possible; the inventAIRy XL solution has enabled us to do just that.

“At PD Ports we’ve set out our strategic priorities to help us achieve our vision, one of which is safety. They are here to guide us when making choices about how we can invest wisely to innovate and grow the business.

“There’s been a significant reduction in health and safety risks since it’s eliminated the need to use scissor lifts in this warehouse for counting stock – and that was one of the primary drivers for our decision to look into automating our inventory counts.”

And not only has the technology made the work environment safer, but it’s also freeing the team up elsewhere.

Mr Borg explained: “By relieving colleagues of this time-consuming and laborious task, their time is now almost exclusively spent doing productive work, which further enhances the service we are delivering to our customers. We’ve also seen an improvement in our order fulfilment time, because we no longer have scenarios where colleagues waste time trying to find misplaced stock.”

Alongside the health and safety benefits and increased staff productivity, PD Ports customers have also seen benefits from greater accuracy that regular, automated stock counts bring – removing the risks of over- or understocking.

RAWview director on integrations Joe Waldron added: “ From the very beginning, it has been our goal to collaborate with the industry’s most innovative companies that align with our vision of fostering a safer, more sustainable, and efficient workplace.

“Our partnership with PD Ports perfectly embodies this objective. Engaging with an organisation whose members not only welcome change but actively embrace it has been a rewarding experience. We anticipate the continued growth of our relationship with the PD Ports team in the future.”

Follow PD Ports on social media here:

Twitter: @PDPorts

Instagram: @pdports

LinkedIn: PD Ports

For all the latest news from across the Teesport complex visit www.teesport.co.uk or follow @Teesport on Twitter.

If you would no longer like to receive these emails please let us know by responding to communications@pdports.co.uk.